Key Takeaways

- Revolutionary Automation: RightHand Robotics is transforming warehouse operations through advanced automation, enhancing efficiency and accuracy in order fulfillment processes.

- Adaptive Technology: Their robotic systems adapt to various product types, ensuring seamless integration with existing workflows and streamlining sorting, picking, and packing tasks.

- Collaboration Focus: By designing collaborative robotics that work alongside human workers, RightHand Robotics enhances productivity while maintaining safety in the workplace.

- Data-Driven Insights: The company utilizes robust data analytics to provide real-time insights for inventory management, enabling businesses to optimize resource allocation and operational efficiency.

- Diverse Applications: RightHand Robotics’ solutions are applicable in multiple industries, including manufacturing, healthcare, and logistics, significantly improving efficiency and productivity.

- Cost Efficiency: Automation leads to reduced labor costs and operational expenses, as well as faster order processing and improved accuracy, fostering more cost-effective operations in various environments.

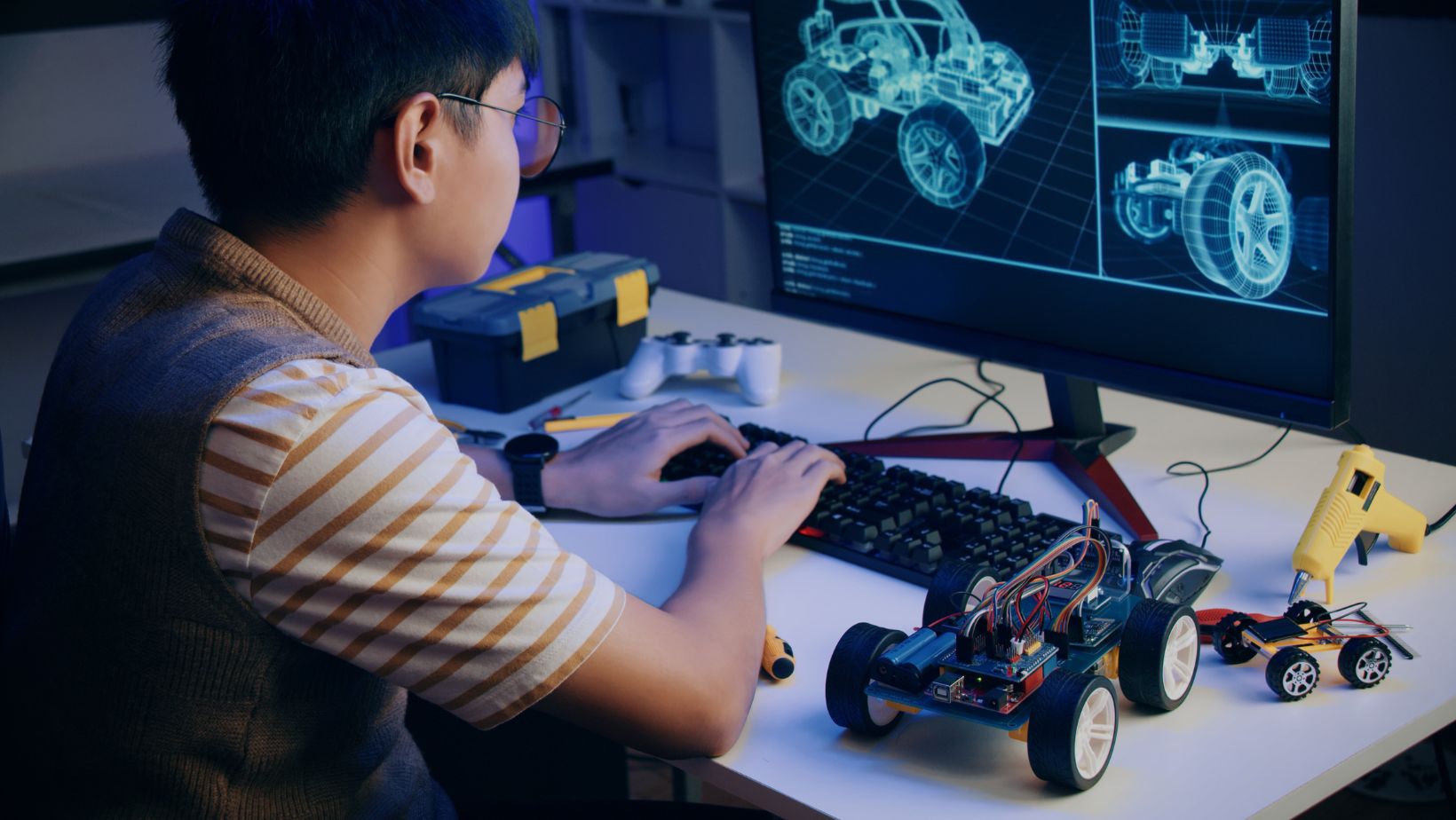

In a world where automation is reshaping industries, RightHand Robotics stands at the forefront of innovation. This company is revolutionizing the way warehouses and distribution centers operate by integrating advanced robotic solutions that enhance efficiency and accuracy. By harnessing the power of artificial intelligence and sophisticated robotic systems, RightHand Robotics is redefining traditional logistics.

As e-commerce continues to surge, the demand for faster and more reliable order fulfillment grows. RightHand Robotics addresses this challenge head-on, offering solutions that not only streamline operations but also adapt to the unique needs of each business. With a focus on collaboration between humans and machines, RightHand Robotics is paving the way for a smarter future in supply chain management.

Righthand Robotics

RightHand Robotics specializes in advanced automation solutions for warehouses and distribution centers. The company’s primary focus lies in developing robotic systems that enhance order fulfillment processes. These systems utilize artificial intelligence and machine learning algorithms to optimize sorting, picking, and packing tasks, thus increasing operational efficiency.

Key features of RightHand Robotics include:

- Adaptive Technology: Robotic systems adjust to varying types of products, ensuring seamless integration with existing workflows.

- Robust Data Analytics: Solutions gather and analyze data in real-time, providing valuable insights for inventory management and performance optimization.

- Collaborative Robotics: RightHand Robotics designs its systems to work alongside human workers, enhancing productivity while maintaining a safe working environment.

The company addresses the challenges posed by rising e-commerce demands through tailored automation solutions. RightHand Robotics emphasizes flexibility, allowing clients to scale operations according to their specific needs. By focusing on innovation and collaboration, RightHand Robotics contributes significantly to shaping the future of supply chain management.

Key Technologies

RightHand Robotics employs several advanced technologies to optimize warehouse and distribution automation. These technologies enhance order fulfillment, improve operational efficiency, and promote collaboration between human workers and robots.

Automation Capabilities

Automation capabilities form the backbone of RightHand Robotics’ solutions. These systems streamline the sorting, picking, and packing of products, significantly reducing manual labor. Robots efficiently navigate warehouses, utilizing high-precision sensors to identify, grasp, and move items. Adaptive algorithms enable systems to adjust to diverse product types, maximizing throughput and minimizing errors. Integration with existing warehouse management systems ensures seamless operation, allowing businesses to scale their logistics operations according to specific requirements.

Machine Learning Integration

Machine learning integration enhances RightHand Robotics’ ability to process data and optimize workflows. Algorithms learn from real-time operational data, continuously improving accuracy in item recognition and handling. This adaptive learning fosters predictive maintenance, reducing downtime and improving reliability. Enhanced data analytics provide actionable insights, enabling businesses to make informed decisions about inventory management and resource allocation. As machine learning models evolve, the systems become increasingly proficient, driving efficiency and performance across various warehouse operations.

Applications in Various Industries

RightHand Robotics’ advanced robotic solutions find applications across multiple industries, significantly enhancing efficiency and productivity. Their innovative technologies streamline processes in manufacturing, healthcare, and logistics.

Manufacturing

Manufacturing benefits from RightHand Robotics through enhanced assembly line efficiency and precision. Robotic systems automate repetitive tasks, such as pick-and-place operations, allowing human workers to focus on more complex duties. Adaptive algorithms manage diverse product types, ensuring seamless integration in dynamic production environments. Data analytics enables real-time monitoring and optimization, reducing operational downtime and maintaining high throughput.

Healthcare

Healthcare incorporates RightHand Robotics to improve supply chain management and medication fulfillment. Automated robots handle the sorting and delivery of medical supplies, minimizing errors in critical environments. Robotics systems also aid in managing inventory, ensuring timely restocking and enhancing operational efficiency. By streamlining logistical workflows, healthcare facilities can focus more on patient care, resulting in improved health outcomes.

Logistics

Logistics heavily relies on RightHand Robotics to optimize warehousing and distribution processes. Robotic solutions facilitate efficient sorting, picking, and packing of products, significantly reducing lead times. Collaborative robotics work alongside human workers, enhancing productivity and ergonomics. The incorporation of machine learning aids in accurate demand forecasting and inventory management, ensuring consistent stock availability while minimizing waste.

Advantages of Righthand Robotics

RightHand Robotics offers significant advantages that enhance operational capabilities. These benefits include notable efficiency improvements and cost reduction.

Efficiency Improvement

Efficiency improvements arise from automated systems that streamline processes related to sorting, picking, and packing. Robotic systems utilize AI-driven algorithms to identify and handle various product types. By integrating high-precision sensors, these robots maximize throughput while minimizing errors, ensuring quicker order fulfillment. Collaborative robotics also allow human workers to focus on complex tasks, thus optimizing workforce productivity. Real-time data analytics further enhance efficiency by providing actionable insights for inventory management and resource allocation, leading to faster decision-making.

Cost Reduction

Cost reduction results from lower labor costs and decreased operational expenses. Automated systems reduce the reliance on manual labor, allowing companies to reallocate resources to other critical areas. By decreasing order processing times and minimizing errors, RightHand Robotics’ solutions reduce overhead costs associated with returns and rework. Additionally, predictive maintenance driven by machine learning enhances the longevity of robotic systems, resulting in lower capital expenditure over time. Overall, these advantages foster a more cost-effective operation in warehouses and distribution centers.

Challenges and Limitations

RightHand Robotics faces various challenges and limitations in the automation landscape. These obstacles impact operational efficiency and overall market viability.

Technical Hurdles

Technical hurdles include integration issues with existing warehouse systems. Adapting robotic solutions to diverse environments poses challenges as each facility might employ different software and hardware configurations. Additionally, developing high-precision sensors that accurately recognize a wide range of products remains integral to optimal functionality. Algorithms must continuously evolve to address inconsistencies in item handling, which can lead to errors and inefficiencies. Moreover, ensuring robust data analytics that offers real-time insights requires substantial investments in technology and continuous updates. These technical limitations necessitate ongoing research and development to maintain competitiveness.

Market Competition

Market competition intensifies as more companies enter the robotics space. Multiple players develop advanced automation solutions, driving increased innovation but also creating pressure on pricing and market share. RightHand Robotics must differentiate its offerings with superior technology and unique features. Staying ahead involves not only enhancing existing capabilities but also addressing evolving customer needs amidst rapidly-changing industry demands. Collaborations and partnerships can mitigate some competitive pressures, but the landscape remains crowded, making strategic positioning essential for sustained success.

Warehouse Automation

RightHand Robotics stands at the forefront of warehouse automation, effectively addressing the growing demands of e-commerce. Its innovative robotic solutions not only streamline order fulfillment but also foster collaboration between humans and machines. By leveraging advanced AI and machine learning, the company enhances operational efficiency across various sectors, from manufacturing to healthcare.

As RightHand Robotics continues to evolve, its focus on flexibility and tailored solutions positions it well within a competitive landscape. The commitment to overcoming challenges and driving innovation ensures that it remains a key player in shaping the future of supply chain management. With ongoing advancements, the potential for improved efficiency and cost reductions only grows, making RightHand Robotics a vital partner for businesses aiming to thrive in an increasingly automated world.