Key Takeaways

- Adaptability of Robots: Universal robotics incorporates versatile robots capable of performing multiple tasks across various industries, enhancing productivity and collaboration.

- Advanced Technologies: Key technologies, including AI, machine learning, and robotic process automation, enable universal robots to learn from their environments and streamline operations.

- Sector Applications: Universal robotics is transforming industries such as manufacturing, healthcare, and agriculture by increasing efficiency, reducing labor costs, and addressing labor shortages.

- Cost Efficiency: The implementation of universal robotics leads to significant cost savings, with businesses reporting operational cost reductions of up to 20-25% through automation.

- Safety Enhancements: Universal robots improve workplace safety by taking over high-risk tasks, leading to a substantial decrease in workplace accidents and fostering a safer environment for human workers.

- Future Potential: The growing demand for universal robotics is set to shape the future of work, promising to revolutionize operations across multiple sectors for better efficiency and effectiveness.

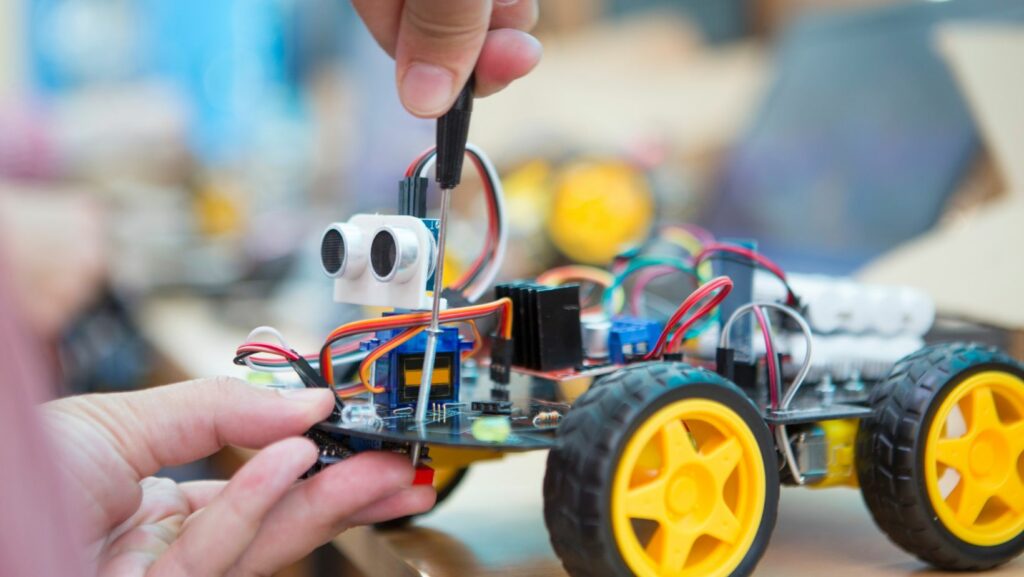

In a world where technology evolves at lightning speed, universal robotics stands out as a game-changer. This innovative field focuses on creating robots that can adapt to a variety of tasks across different industries. From manufacturing to healthcare, these versatile machines are designed to enhance productivity and efficiency, making them invaluable assets in today’s economy.

As businesses seek ways to streamline operations and reduce costs, the demand for universal robots continues to grow. These intelligent systems not only perform tasks traditionally handled by humans but also learn and improve over time. With advancements in artificial intelligence and machine learning, the future of universal robotics promises to revolutionize how we work and live, paving the way for a smarter, more automated world.

Universal Robotics

Universal robotics involves the development of robots capable of performing a wide range of tasks across diverse industries. These adaptable systems integrate advanced technologies, including artificial intelligence (AI) and machine learning, enabling them to learn from their environments and improve over time. They demonstrate flexibility, making them suitable for various applications, from manufacturing and logistics to healthcare and agriculture.

Key features of universal robotics include:

- Adaptability: Universal robots can adjust to different tasks and work alongside human colleagues, enhancing collaboration and productivity.

- User-friendly Programming: Many universal robots offer intuitive programming interfaces, allowing operators with minimal technical expertise to deploy and control them effectively.

- Cost Efficiency: By streamlining operations and reducing labor costs, universal robotics significantly improve a company’s bottom line.

- Reduced Downtime: Advanced sensors and real-time monitoring capabilities minimize operational interruptions, optimizing workflow efficiency.

The demand for universal robotics continues to rise as industries seek innovative solutions. As technology evolves, these robots will likely play an increasingly critical role in daily operations, addressing labor shortages and improving overall performance in various sectors.

Key Technologies in Universal Robotics

Universal robotics harnesses several key technologies that enable robots to function effectively across various tasks and industries. These innovations play a crucial role in enhancing the capabilities of adaptable robotic systems.

Automation Solutions

Automation solutions streamline operations by enabling robots to perform repetitive tasks with precision. These systems utilize advanced algorithms to manage workflows, reducing human intervention. Notable automation technologies include:

- Robotic Process Automation (RPA): Automates rule-based tasks within digital environments.

- Vision Systems: Utilizes cameras and sensors to enable robots to interpret and respond to visual information.

- Artificial Intelligence (AI): Powers decision-making processes, allowing robots to learn and adapt over time based on real-time data.

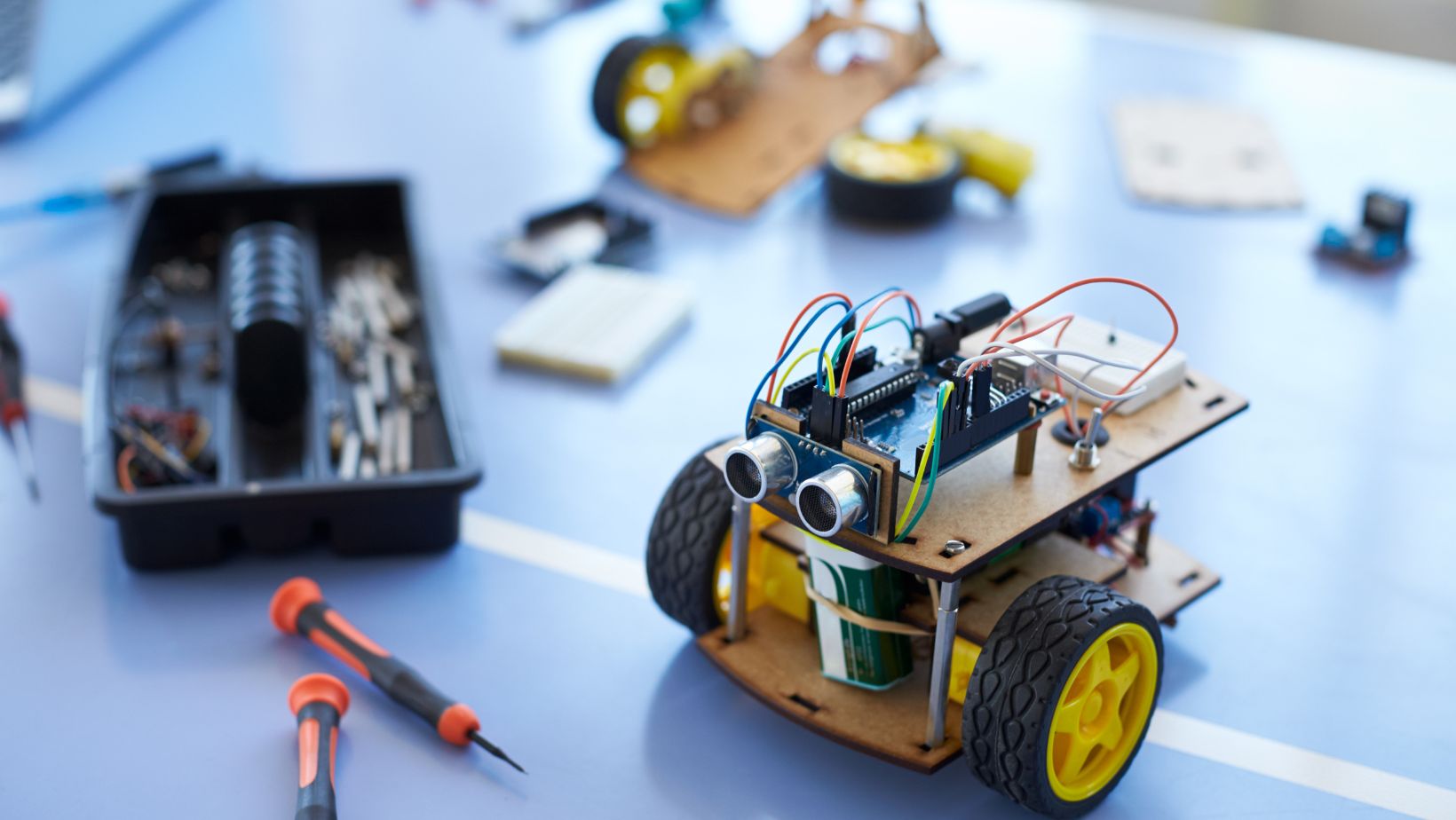

Collaborative Robots

Collaborative robots, often referred to as cobots, are designed to work alongside humans safely. These robots enhance productivity by assisting workers in various tasks without compromising safety. Key characteristics of collaborative robots include:

- Safety Features: Equipped with sensors to detect human presence, minimizing the risk of collisions.

- User-Friendly Programming: Allows operators to set up and operate cobots easily, often using intuitive interfaces.

- Versatility: Capable of performing multiple functions, from assembly to packaging, adapting to various manufacturing environments.

The integration of these technologies in universal robotics significantly contributes to the evolution of industries, maximizing efficiency and minimizing operational costs.

Applications of Universal Robotics

Universal robotics shows considerable versatility across various sectors, enhancing productivity and offering innovative solutions tailored to specific industry needs.

Manufacturing Industry

Universal robotics transforms manufacturing processes by leveraging automation to improve efficiency and consistency. Robots equipped with advanced sensors perform tasks such as assembly, welding, and quality control. Collaborative robots (cobots) work alongside human operators, increasing safety and productivity. The ability to program robots for multiple tasks reduces production downtime and allows for rapid reconfiguration during transitions between product lines. According to a report from the International Federation of Robotics, industrial robot installations reached over 381,000 units globally in 2020, demonstrating significant growth in this field.

Healthcare Sector

In the healthcare sector, universal robotics enhances patient care and operational efficiency. Robots assist in surgeries, providing precision and reducing recovery times. Autonomous mobile robots transport medication and supplies within hospitals, decreasing human error. Universal robots also assist with rehabilitation, offering personalized therapy programs that adapt to individual patient needs. A study published by the Journal of Robotics in Healthcare indicates that robotic-assisted surgeries lead to a 20% reduction in postoperative complications.

Agriculture

Universal robotics plays a pivotal role in modern agriculture, addressing labor shortages and improving crop yields. Robots streamline processes such as planting, harvesting, and crop monitoring. Drones equipped with imaging technology assess crop health and optimize resource allocation. Automated systems reduce the need for manual labor while increasing precision in tasks like irrigation and pesticide application. According to a report by Markets and Markets, the agricultural robotics market is projected to reach $20.6 billion by 2025, reflecting the growing integration of robotics in farming practices.

Benefits of Universal Robotics

Universal robotics delivers numerous advantages across industries, enhancing overall performance and operational effectiveness. Key benefits include enhanced efficiency, cost reduction, and improved safety.

Enhanced Efficiency

Enhanced efficiency serves as a primary benefit of universal robotics. These adaptable robots execute repetitive tasks with precision, increasing productivity significantly. Industries experience faster production cycles as robots perform assembly, quality control, and packaging tasks. Many companies report up to a 30% increase in operational speed, enabling them to meet rising demand without compromising quality. Furthermore, real-time data analysis and machine learning allow robots to optimize processes continuously, leading to ongoing improvements in efficiency.

Cost Reduction

Cost reduction represents another crucial advantage of universal robotics. By automating labor-intensive tasks, businesses can decrease labor costs and minimize human error. For instance, factories that employ universal robotics often report operational costs dropping by as much as 20-25%. Additionally, reduced downtime, thanks to reliable automated systems, further contributes to significant savings. The initial investment in robotic technologies often yields favorable returns, with many organizations recouping costs within three years.

Improved Safety

Improved safety stands out as an essential benefit of universal robotics. These systems often integrate advanced sensors and safety features, fostering secure collaboration between robots and human workers. Many industries experience a decrease in workplace accidents due to robots assuming dangerous tasks. For example, in manufacturing environments, the incidence of injuries can drop by over 40% when utilizing collaborative robots (cobots). Enhanced safety protocols not only protect human workers but also promote a healthier workplace culture conducive to higher morale and productivity.

How Robotics Operate

The rise of universal robotics marks a pivotal shift in how industries operate. As adaptable robots become integral to various sectors, they promise to redefine productivity and efficiency. Their ability to learn and adapt ensures that businesses can respond swiftly to changing demands while maintaining cost-effectiveness.

With advancements in AI and machine learning, the future looks bright for universal robotics. These technologies not only enhance operational capabilities but also create safer workplaces. As industries continue to embrace these intelligent systems, the benefits will only grow, paving the way for a more automated and innovative world.